Discover Exceptional Rubber Floor Coatings

At Dyon Construction, we specialize in providing premium rubber floor coatings designed to enhance the safety, durability, and aesthetics of your floors. With over 25 years of experience, our team excels in applying rubber coatings that meet the unique needs of residential, commercial, and industrial clients. Using advanced techniques and high-quality materials, we ensure that every project is completed to the highest standards of quality and performance.

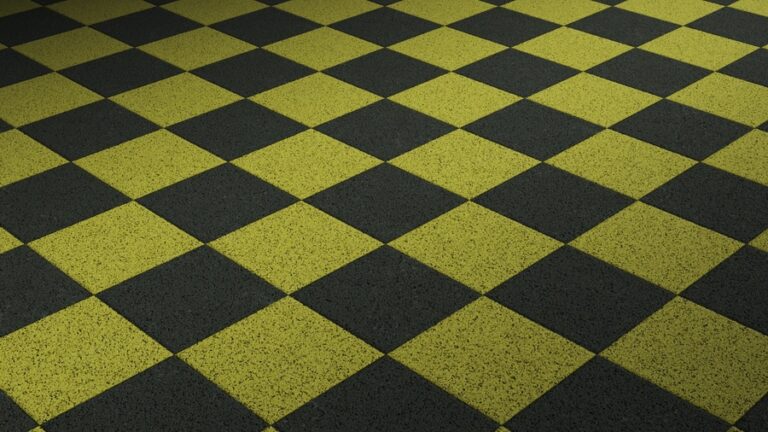

Our rubber floor coatings are not only visually appealing but also provide a safe, low-maintenance surface that enhances the functionality and longevity of your floors. Whether for gyms, play areas, commercial kitchens, or industrial facilities, our rubber floor coatings offer the perfect blend of durability and safety.

What is Rubber Floor Coating?

Rubber floor coating is a protective layer applied to floors to enhance their durability, slip resistance, and aesthetic appeal. This coating is made from high-quality rubber materials that provide a resilient surface capable of withstanding heavy foot traffic, impacts, and various environmental conditions. The application process involves preparing the existing floor surface, applying a primer if necessary, and then coating the floor with rubber material to achieve a seamless, protective finish.

Rubber floor coatings are ideal for a variety of settings, including commercial kitchens, gyms, playgrounds, and industrial facilities. They offer excellent slip resistance, cushioning, and noise reduction, making them a versatile and practical flooring solution.

Enhance and protect your floors with our expert rubber floor coatings

Contact Dyon Construction today to learn more and get a free quote.

Our Rubber Floor Coating Services

Gym and Fitness Flooring

Provide a safe and durable surface for your gym or fitness center with our rubber floor coatings. These coatings offer excellent shock absorption and slip resistance, making them ideal for high-impact activities.

Playground and Recreational Flooring

Ensure the safety of children in playgrounds and recreational areas with our rubber floor coatings. These coatings provide a cushioned, slip-resistant surface that reduces the risk of injuries from falls.

Commercial Kitchen Flooring

Maintain a clean and safe environment in commercial kitchens with our rubber floor coatings. These coatings are resistant to grease, moisture, and heavy foot traffic, ensuring a durable and hygienic surface.

Industrial and Warehouse Flooring

Enhance the durability and safety of your industrial or warehouse floors with our rubber floor coatings. These coatings provide excellent resistance to heavy machinery, chemicals, and abrasions, ensuring long-lasting performance.

Garage and Workshop Flooring

Upgrade your garage or workshop with our rubber floor coatings. These coatings offer a durable, slip-resistant surface that is easy to clean and maintain, making them ideal for high-use areas.

Benefits of Rubber Floor Coatings

Durability and Longevity: Our rubber floor coatings are designed to withstand heavy foot traffic, impacts, and various environmental conditions, ensuring a long-lasting and resilient surface for your floors.

Slip Resistance: Rubber floor coatings provide excellent slip resistance, reducing the risk of accidents and injuries. This makes them ideal for areas prone to spills and high foot traffic.

Comfort and Safety: The cushioning properties of rubber floor coatings enhance comfort and safety, providing a shock-absorbing surface that reduces fatigue and the risk of injuries from falls.

Noise Reduction: Rubber floor coatings help to reduce noise levels by absorbing sound, making them an excellent choice for gyms, fitness centers, and other noisy environments.

Low Maintenance: Rubber floor coatings are easy to clean and maintain. Their seamless, non-porous surface resists stains, moisture, and dirt, making regular maintenance simple and efficient.

The Process of Applying Rubber Floor Coatings

At Dyon Construction, we follow a detailed, step-by-step process to ensure your rubber floor coating project meets our high standards of quality and durability:

Consultation

- We begin with a free consultation to discuss your needs and preferences. Our experts will assess your floors and recommend the best rubber coating solution for your specific requirements.

Surface Preparation

- Proper surface preparation is essential for successful rubber floor coating application. We clean and repair the existing surface to ensure it is smooth and free of contaminants.

Primer Application

- If necessary, we apply a primer to enhance adhesion and create a strong bond between the existing floor and the rubber coating.

Rubber Coating Application

- Our experienced team applies the rubber coating with precision, ensuring even coverage and a smooth finish. We use specialized equipment to achieve the best results.

Curing

- The rubber coating is allowed to cure, forming a hard, durable surface. This process ensures the coating bonds effectively with the existing floor, providing long-lasting protection.

Final Inspection

- Once the application is complete, we conduct a final inspection to ensure the quality and finish meet our high standards. Any necessary touch-ups are performed at this stage.

Why Choose Dyon Construction?

- Experience and Expertise: With over 25 years in the industry, Dyon Construction has the knowledge and skills to deliver exceptional rubber floor coating solutions. Our team is trained in the latest techniques and uses the best materials to ensure high-quality results.

- Customer Satisfaction: We prioritize our customers’ satisfaction and are committed to delivering top-notch service. From the initial consultation to the final inspection, we work closely with you to ensure your rubber floor coating meets your expectations.

- Affordable Pricing: Our competitive pricing ensures you get the best value for your investment. We offer transparent quotes with no hidden fees, allowing you to make an informed decision.

- Quality Materials: We use only premium materials to ensure the durability and longevity of your rubber floor coatings. Our commitment to quality means you can trust that your floors will stand the test of time.

Frequently Asked Questions for Epoxy Flooring

- Q: How long does the rubber floor coating process take?

A: The rubber floor coating process typically takes 1-3 days, depending on the size and condition of the area. This includes surface preparation, coating application, and curing time.

- Q: What are the benefits of rubber floor coatings?

A: Rubber floor coatings provide numerous benefits, including increased durability, slip resistance, comfort, noise reduction, and low maintenance. They are ideal for various applications, from gyms and playgrounds to industrial floors.

- Q: Can rubber floor coatings be applied to existing floors?

A: Yes, rubber floor coatings can be applied to existing floors. Proper surface preparation, including cleaning and repairing any cracks, is essential for successful application.

- Q: How do you maintain a rubber-coated floor?

A: Maintaining a rubber-coated floor is straightforward. Regular cleaning with a mild detergent and occasional resealing are usually sufficient to keep the surface looking its best. Avoid using harsh chemicals or abrasive cleaners.